Waste Sustainable Conversion

In Waste Sustainable Conversion Group at Cimav the specialists do research on waste materials to conceive how to transform them into advanced materials and fuels, which latter could be employed mainly for water pollution control. This transformation is developed through environmental friendly processing, avoiding thus chemicals and solvents usage which are risky for human health and ecological systems.

The term sustainability demands to comply with different issues in order to achieve the proper transformation of wastes. One successful topic at Cimav is the preparation of nanocomposite polymeric membranes for being used in salts removal from well-water in filtration process.

Agroforestry wastes (also known as biomass waste) are used for developing polymeric membranes. Annually 50 billion tons of these wastes are discarded in the whole world, being the cellulose content on them a strategic value, due to their esterified derivatives can be converted into semi-permeable films (polymeric membranes).

Researchers at Cimav besides producing these materials, also focus on conversion processes under sustainable development guidance.

As an example, in order to obtain pulp with high cellulose concentration from biomass waste, at Cimav have been performed ethanosolv reactions and extraction from ionic liquid dissolution. In both cases the processes operate at lesser temperature in comparison with traditional methods actually employed by pulp and paper industry. Even more important, the usage of reactants with chlorine and sulfur is eliminated, because of their interaction with lignin the black liquor are generated, highly impacting on water and soil pollution.

Membrane

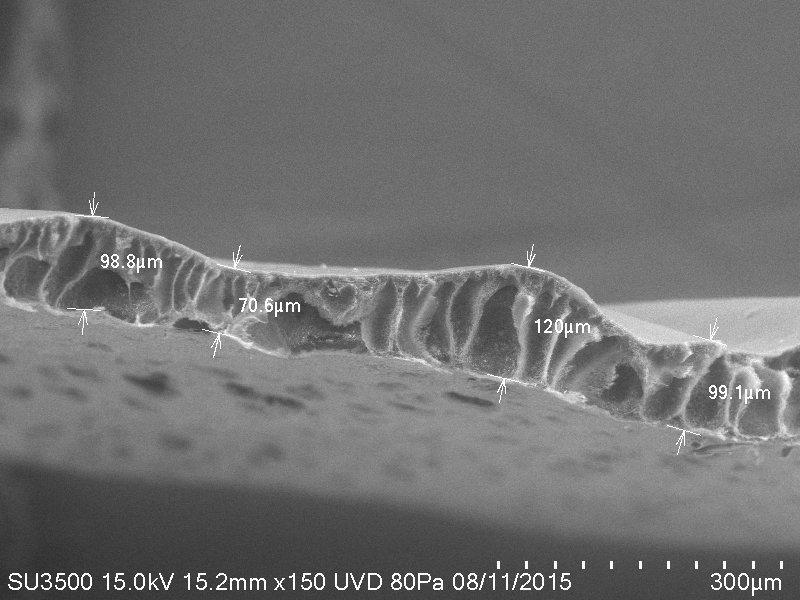

Once sustainable development premises have been satisfied, researchers at Cimav have made membranes from cellulose acetates with nanometric fillers, such as esterified technical lignins. Moreover, these membranes must accomplish with certain characteristics for being competitive in front of membranes obtained from oil-derived polymers (polysulfones, polyamides, polyacrilonitrile). Once these desired morphological and structural properties are reached in the cellulose acetate films, the membranes are tested in process modules in order to classify them into ultrafiltration or reverse osmosis membranes.

Project scientific basis

To study lignocellulosic biomass interactions with novelty reaction media or by extraction in novel solvents, in order to get cellulose derivatives for membranes development for desalination. These membranes must comply with a structural design were salts rejection would be maximum, water permeability increases with lesser operation pressure and both biofouling and concentration polarization are minimized.

In the other hand, a research branch has been developed focused on activated carbons synthesis and modification with iron and aluminum with the purpose of arsenic and fluoride removal from well-water.

Pollution Control Area through these projects has promoted human resources formation and publishing research papers on high impact indexed scientific journals.

- Bioethanol production through cellulose enzymatic hydrolysis after biopolymer recovery from lignocellulosic biomass.

- Sanitary Landfill Leachate Biochemical Treatment

- Life Cycle Assessment for both nanocompounded polymers and waste material conversion into energy (combustion in rotary kiln).

- Kinetic and equilibrium studies for metal adsorption from wastewater into waste biomaterials.

- Degradation and stability assessment for nanocompounded biopolymers.