Materials and Structures Mechanics

At a world level, designers of products from all industries use computational simulation as a tool for the designing virtual prototypes with the main purpose of reducing the expenses generated by the physical validation of prototypes designed on a trial and error basis. Furthermore, simulation makes possible to have more efficient industrial processes and products that offer a security added value.

In addition, by using simulations, it is possible to enhance the human resources and materials management, as well as to generate a better knowledge of the product functioning. Usually, these factors are determinant for a company that tries to improve its performance and to have a technological breakthrough.

At the Advanced Materials Research Center, Cimav (Centro de Investigación en Materiales Avanzados), a multidisciplinary team of specialists who are part of the Modelling of Materials and Industrial Processes group develops models and simulations of the mechanical behavior of materials and structures, for subsequent validation by means of physical tests. The specialists do have outstanding success stories in different types of industries, including aeronautics.

Success cases

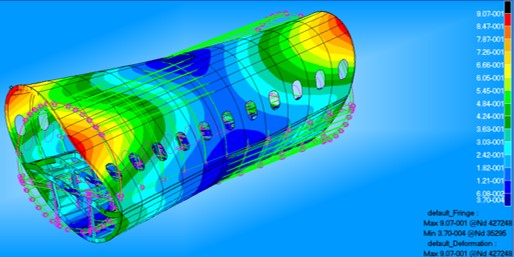

Vibration mode in a fuselage and displacements in a hydraulic line bracket.

In the particular case of the aeronautics industry, the group worked for Labinal de Mexico S. A. de C. V., leading firm in the sector services and part of the prestigious group Safran. The research group at Cimav developed a software that allows to automate the calculation and analysis tasks to simulate the mechanical response of cable and hydraulic lines supports, making possible to optimize and validate designs of these components in commercial aircrafts applications.

The parts that hold both the cable and the hydraulic lines are subject to high stress mainly due to vibrations generated in the different flight stages. The software developed by Cimav makes possible to display stresses, strains and vibration modes in the components studied, which helps the user to remove redundant elements which add weight but that do not represent a structural benefit for the aircraft.

Thanks to the use of these simulation tools, the user lowers the costs of hydraulic lines and cabling installation, which subsequently translates into lower fuel consumption and pollutant emissions to the environment, all this without neglecting the aircraft mechanical integrity. In addition to these benefits for the customer, the project realization had additional products such as the copyright registration by the company and the company’s personnel training in structural mechanics and the system use.

In this topic, the specialists at Cimav carried out calculations to define the structure and materials to have more comfortable, ergonomic, light and resistant new seats for commercial aircrafts that will be produced by Zodiac Aerospace.

The researchers together with specialists from the company proposed improvements to the original model and created a virtual prototype which was validated by virtual tests simulating extreme usage conditions. Once the theoretical validation was made, the company proceeded to produce the physical prototype with the design being validated by means of physical tests.

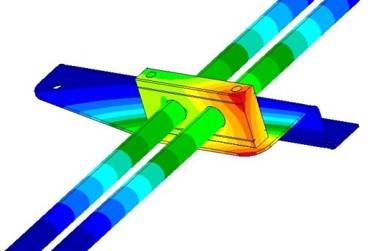

Example of crane with basket.

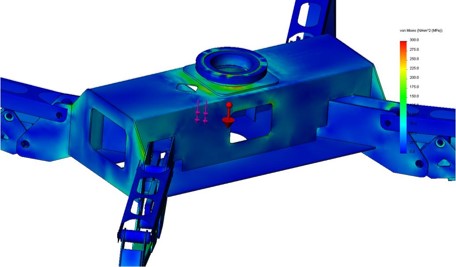

Von Mises stress maps in the crane boom and chassis.

This project was carried out for Grupo Industrial Keila, company specialized in the sale of crane with baskets and platform cranes. For this work, researchers at Cimav streamlined the design of some cranes prototypes aimed at reducing the cost and weight, and ensuring the mechanical integrity and stability at every moment. In addition, the materials to be used were defined for every single element of the cranes. Then, in order to check those theoretical calculations, the company developed physical prototypes that were already validated. Today, those cranes already are manufactured and marketed by the company, achieving in such a way another success case.

The above success cases are an example of the potential of the researchers at Cimav in this work area.

Others services and projects offered to companies are:

- Structural calculations.

- Stresses and strains analyses

- Optimization of pieces and structures designs

- Processes modelling and simulation

- Modelling and simulation of materials behavior based on and validated through experimentation

- Software development

- Thermomechanical tests (bending, tension, compression, DMA, toughness) as well as impact and hardness measurement tests.

Development of MAC LAM V.1.0 and 2.0 software for the mechanical analysis of composite and laminate materials

This simulation software called Mechanical Analysis of Composites and LAMinates (MAC LAM) was developed by the end of 2004 with academic purposes, not excluding the private sector which can make use of the software under certain conditions. One of its main features is the free use and the system configuration in different languages. http://maclam.cimav.edu.mx.

MAC LAM makes possible to analyze the mechanical properties of composite materials as well as to predict the characteristics that the laminated materials will have, for example, laminated materials used by the aerospace industry. Some of the properties that can be analyzed are flexibility, mechanical strength and stiffness.

This software was developed in close collaboration with the École Nationale des Ponts et Chaussées in France and the programming support of students of the Instituto Tecnológico de Chihuahua II.

Development of finite element software SEDEF V.1.0

Globally, simulation and finite element analysis have a great relevance. However, in Mexico, the poor promotion at an academic level is consequence of the high costs of such software. Therefore, specialists at Cimav are developing a flexible, friendly, and free finite element software to avoid the actual scheme which requires to pay in order to make use of such specialized software.

The software will solve numerically, by means of a finite element technique, generic differential equations that can be applied to problems in structural mechanics, fluid mechanics, diffusion of chemical species, and heat transfer, among others.

The software will be mainly for academic purposes and will make possible for students to perform calculations regarding real industrial problems, situations that nowadays are not carried out because of the complexity implied by the analytical solution of equations. This work is carried out in collaboration with the Instituto Tecnológico de Chihuahua II and with the support of master degree students from the Universidad Autónoma de Chihuahua conducting thesis research in structural engineering.

The main research lines of this group are:

- Nonlinear behavior models and prediction of failure in adhesives and structural adhesive bonding.

- “Layer-wise” models and their implementation in finite element codes for laminated plates and shells analyses.

- Modelling and simulation of photovoltaic cells operation.

In addition, there are two projects available for software development mainly for educational purposes: MACLAM software and SEDEF software.